Rethinking Biodegradable Packaging: A Regenerative Approach

The Challenge with Traditional “Biodegradable” Packaging

Biodegradable packaging has long faced skepticism. Critics argue that most materials marketed as biodegradable don’t fully break down under real-world conditions. In places like California, regulatory restrictions even prohibit the use of “biodegradable” labeling unless stringent decomposition criteria are met. Why? Because most biodegradable plastics fail to degrade in landfills, dry climates, or natural environments due to a lack of oxygen, moisture, and microbial activity (California Public Resources Code, Section 42357).

Additionally, biodegradable materials have often been criticized for disrupting recycling streams. Many biodegradable additives weaken plastic polymer structures, rendering them unsuitable for recycling. Others begin breaking down in wet conditions, compromising product integrity before disposal. Finally, cost concerns remain a major hurdle in adopting alternative packaging solutions.

The Reality of Plastic Waste: Why Recycling Alone Isn’t Enough

Recycling, while essential, has not solved the global plastic crisis. Consider these statistics:

- The U.S. recycles less than 5% of plastic waste (EPA, 2023).

- PET—the most recycled plastic—only achieves an 18% recycling rate in the U.S., while Europe averages 60% and some countries exceed 90% (Plastics Europe, 2023).

- 14 million metric tons of plastic enter the ocean annually, causing severe harm to marine life (UNEP, 2022).

While legislation mandating recycled content in packaging has improved recycling rates in some regions, the reality remains: recycling alone isn’t enough.

A Game-Changer in Biodegradable Plastic?

A company called Biodegradable Future may have the answer by offering a true regenerative solution.

Rather than relying on conventional biodegradable plastics that fail in real-world conditions, Bio Future (BFA) has developed a regenerative, non-toxic, recycling-

friendly additive that ensures plastics fully break down into biomass, CO₂, and water under microbe-rich conditions. Here’s how it works:

Recycling-Friendly

Unlike conventional biodegradable plastics that disrupt recycling, BFA’s technology is fully compatible with existing mechanical and chemical recycling processes. Plastics containing BFA’s additive maintain their structural integrity in recycling streams and only decompose when exposed to microbial environments like landfills, soil, or industrial composting sites.

No Microplastics, Just Biomass

Many biodegradable plastics degrade into microplastics, which persist in the environment and contaminate ecosystems. BFA’s additive ensures complete breakdown into natural elements—no microplastics, no toxic residues. This aligns with ASTM D5511 and ISO 15985 standards for anaerobic biodegradation and complies with RoHS, FDA, EU Food Safety (Regulation No. 1935/2004), and Intertek Green Leaf Certification.

Universal Application & Certification

- Works across PET, PP, HDPE, LDPE, PS, PVC, PLA, and even textiles (polyester, nylon)

- Fully certified for food contact (FDA, EU) and safe for consumer use

- Meets global sustainability compliance standards (ASTM, ISO, RoHS, FDA, REACH, and Intertek Green Leaf)

Cost Comparison: Regenerative Plastics vs. PCR

The perception that sustainable materials are too costly is outdated. Here’s how BFA’s additive stacks up against post-consumer recycled (PCR) content based on a 60-cent per pound virgin plastic baseline:

- BFA Additive: +10-15% cost → 66-69 cents per pound

- 25% PCR Content (PCR is typically 25% more expensive than virgin): 64 cents per pound

- 50% PCR Content: 68 cents per pound

With PCR supply shortages and fluctuating prices, BFA’s solution provides cost stability while ensuring a real end-of-life solution.

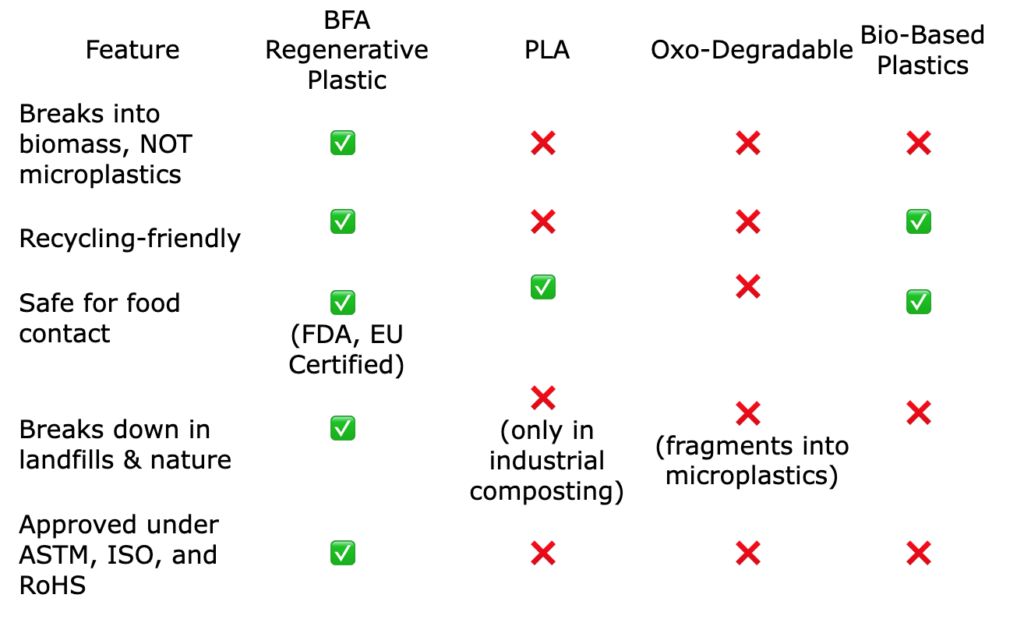

How BFA Compares to Other “Biodegradable” Plastics

Time for a New Conversation: Beyond Traditional Sustainability

Consumers are demanding better—they want solutions that don’t just delay waste but eliminate it responsibly. Traditional biodegradable plastics, PLA, and oxo-degradable materials have failed to deliver on their promises. The future isn’t about just reducing harm; it’s about regeneration.

Perhaps it’s time for brands to embrace and communicate the benefits of truly biodegradable regenerative plastics, shifting the conversation toward responsible, science-backed innovation.

#Regeneration #BiomassConversion #MicroplasticFree #RecyclingFriendly #BioFuture

Written by Peter Lennox , March 17th, 2025